In July 2024, MKU Limited, a global defense and homeland security company based in Kanpur, India, invited BodyArmorNews.com to its headquarters. From a visit to their corporate office, electro-optronics facility, and two spacious factories housing hi-tech equipment, BodyArmorNews.com gained an intimate understanding into MKU’s operations. Here’s what we learnt.

Founded in 1982 by GK Gupta, a lock-maker with big dreams, MKU Limited (formerly known as M. Kumar Udyog) has now become a global leader in the security industry. The company found its place in defense at a time of political upheaval: the Kargil War of 1999 . As the Indian army struggled to hike over the rugged, snowy terrain of the North, MKU Limited took responsibility for the Jawaans of India and supplied a large order of snow boots at no extra cost. Then on, the mission became clear…To serve those who serve us.

Almost four decades later, the company is branched into two divisions. The line of solutions for soldier and platform security is known as KAVRO Protection. Derived from the Hindi word for armor, Kavach, the series includes ballistic helmets, body armor and armor inserts, ballistic shields, and retrofitted armor for air, land, and naval vessels. Headed by Prachi Gupta, the daughter of MKU’s chairman, and one of the few women in the field, NETRO Optronics designs and develops electro-optronic devices for night vision, thermal detection, and soon, a combination of the two. From the Sanskrit word, Netra, eyes, the NETRO division finds solutions for aiming, the situational awareness of vehicles, and driver night sights for tanks.

The company’s electro-optronics division has its own facility in Kanpur, where all research, manufacturing, and quality assessment takes place. With Raghav Jain as the General Manager, the factory produces up to 30 sets per day, employing 60 dedicated blue-collar workers. The R&D is headed by Varun Singh from IIT Kanpur, a department employing over 20 dedicated engineers, in a roomful of mock-ups, whiteboards, and design specifications. The division’s novel Aviation Night Vision Goggles are specially crafted for pilots, and took about 400 days to produce. After a process of meticulous research and unforgiving testing, 200 units of the goggles have already been ordered by the Indian Air Force.

Sone Ki Chidiya

MKU’s headquarters are a sweet-spot for manufacturing armor. The city of Kanpur has a history in the field that goes back to World War I. Under British-ruled India, harnesses and saddles for horses in battle were manufactured here. Whether it is some of the most intelligent engineers from the Indian Institute of Technology, brain, or a dedicated labor force, brawn, now is not the first time Indian-made equipment finds its way to the global front. Yet, of late, the Indian defense market (and stocks such as HAL, MDL, Cochin Shipyard) has been growing rampantly: according to government officials, the country expects to achieve an annual export target of €4 billion by the end of 2025. MKU Limited is headquartered at the right place, at the right time.

Aside from brain and brawn, a few of the following factors position India as the Sone ki Chidiya, Golden Bird, of the global body armor industry.

Launched in 2014, the Make in India campaign has established new industrial regulations and directed a lot of funding toward the transformation of India as a capable defense exporter, abandoning a long habit of import. From the MoD’s budget of 2024, the Defense Acquisition Procedure (DAP) prioritizes domestic firms over foreign entities in terms of procurement, mandating that 65 percent of their contracts are signed by Indian companies. In an effort to promote research in critical defense technologies, the Innovations for Defense Excellence (iDEX) introduced the “ADITI scheme” that grants up to €2.7 million for start-ups working on the R&D of defense solutions. Fortified in 2018, India’s defense corridor sits in Uttar Pradesh (UP), with six nodes: Aligarh, Agra, Kanpur, Chitrakoot, Jhansi, and Lucknow. With an area of about 243,000 square kilometers, UP has a large workforce, a strong manufacturing base, and an improved rating for the Ease of Doing Business. The corridor, and the Uttar Pradesh Expressways Industrial Development Authority overseeing it, gives quick approvals, incentives to defense companies. Moreover, due to an increased need for border security in not only India, but the world, the public sector has happily handed the reigns of arms and armors to the private world.

For a better illustration, here’s how the Indian armor scene compares to that of the EU.

Going Global

Recognizing a trend of localization and an anti-China sentiment across European defense companies, MKU Limited operates also from Sittensen, Germany. Given India’s stage of growth in defense manufacturing, it is in the interest of the EU body armor market to befriend a new player in the field.

Shortly after MKU Limited found its passion for “empowering heroes”, more so, a love for science and innovation put to good use, the company acquired its first international contract in 2003, with the Spanish army. A domino of acquisitions and partnerships across the globe followed. Taking over AST GmbH in Germany, which strengthened MKU’s solutions for platform armor, opening a manufacturing plant in Ras Al Khaimah, UAE, and initiating “MBRACE”, a program where MKU’s channel partners in over 50 countries apply for tenders, share market intelligence to best service the requirements of MKU’s end-users. The company is now in the process of opening another factory in Brazil, to blanket all hemispheres of the world.

Given the company’s global footprint, it is easier for knowledge to be traded, and adapted to different needs. In collaboration with Estonia’s Vegvisir in May 2024, MKU developed advanced Mixed Reality Situational Awareness Systems (MRSAS) for tanks. These systems are now in the process of being integrated into thousands of Indian armored vehicles.

Catering to a host of security-cultures, MKU understands that the West and the East have unique habits: the West’s shiny new toy syndrome differs from the Eastern-inclination to contemporize outdated equipment. At the recent Eurosatory, the company showcased the MW5000: a new sighting system built for grenade launchers, such as an MK-19, and rusty machine guns. Increasing the weapon’s hit capacity by 65 percent, older gear catching dust in storage rooms finds a new lease on life. A batch was recently dispatched to Morocco, proving the sighting system’s relevance in the Middle Eastern market.

Following a presentation on the goings-on of the company by Ritesh Ranjan, the Assistant Marketing Manager at MKU Limited, BodyArmorNews.com visited their factories in Mallawan and Rooma, a short drive out from Kanpur.

In Mallawan

Most companies in the body armor industry serve government clients, relying on tenders, wherein the flow of production depends on the volume of orders. A “good” factory thus, must be prepared for slow days, as well as periods of overtime. The General Manager of the Mallawan Facility, Rajiv Seth, reports, “In times of a surge in orders, the factory can run 24X7 when our 150 employees work in three different shifts”. Over 36 years of industrial experience, and 13 years at MKU, it is evident that Rajiv Seth truly loves machines, and they seem to love him back… Compared to a regular machine breakdown rate of about four percent, Mallawan unit’s machines saw a breakage rate of less than one percent.

MKU Limited imports raw materials from Avient, Teijin Aramid, and other familiar companies, from their number of warehouses scattered across India. But how a sheet of fiber becomes a helmet, for example, follows an intricate operation. Caught on his downtime, Rajiv Seth graciously guided a tour of his factory, describing the production process, and patiently answering our hundreds of follow-up questions.

In a large shed, rolls of Dyneema were stacked upon one another. Here, the fiber is inspected and marked for defects; coated in resin; dried, within three minutes, in an oven; checked again.

If all is well, the sheet moves into another shed, where a Gerber DCS machine cuts it into a desired shape. Still glossy, brought in from America, the Gerber reduces wastage by optimizing the number of shapes that can be cut from a sheet of prepped Dyneema.

In an adjacent room, the 2D helmet cut-outs are bunched together via an ultrasonic seal. There is a QR code on each bunching to track the employee responsible, and the time of production. The basket-shaped helmet is then cut according to the specifications of a design. Speaking highly of the workers’ accuracy, Rajiv Seth shares his plans to install a Laser Cutter, but wonders if it would really be quicker than his staff.

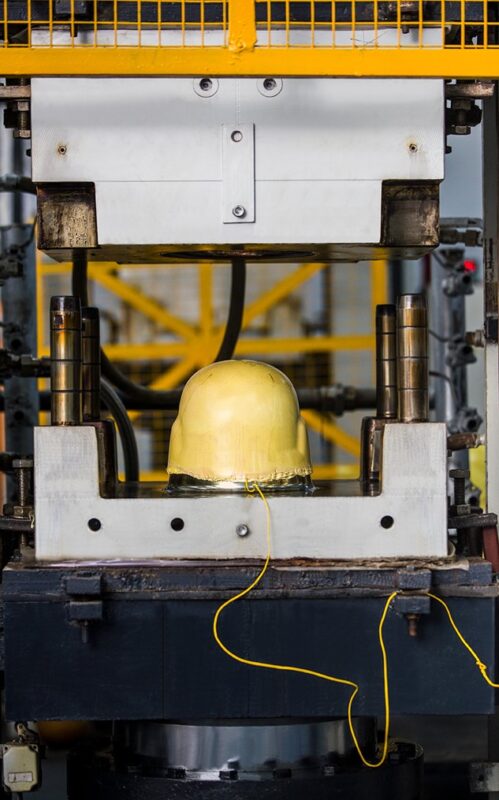

Then the magic happens… In a big hall, a glorious hydraulic steam press molds the helmet into a precise, sturdy, size and shape. Depending on the order, a number of different molds may be taken from storage and affixed on the press.

While BodyArmorNews.com saw behind-the-scenes of MKU’s helmets, different molds for shields, body armor vests, plates, and a Water Jet Cutter, are to be found in Rajiv Seth’s industrial paradise.

When a single detail goes awry in a neatly planned system, valuable time slips away as the entire batch must be rechecked and redone. We inquired into the General Manager’s working hours: “My family knows I am married to my work” He jokes. To keep stress at bay, MKU Limited copyrighted a software called the “Recipe Management System”. This tool provides an overview of each active molding machine, identifies the operator, and presents a graph tracking the temperature and pressure of a steam press over time. Simplifying the comparison of an ideal condition against the actual trial, the system allows for an evaluation of the turnout.

Aside from manufacturing orders from tenders, the Mallawan factory constantly works on developing prototypes with the research and development team. As a result, Rajiv Seth tells, “It happens very rarely that an order is repeated”. When BodyArmorNews.com asked about the most rewarding part of working at MKU, the General Manager highlighted his sharp learning curve, and the excitement behind developing products that are yet to be introduced in the market.

The same molding process was carried out in Germany, but the presses were removed a few years ago, “Due to some constraints by the authorities […]” states Rajiv Seth but is set to resume in the next six months. At a time like this, for orders to be dispatched in the EU, items are manufactured in India and assembled in Germany. The Mallawan factory is also equipped with machines such as the VAM, Smoke Absorber Device that help MKU Limited comply with India’s emission restrictions.

In Rooma

Once a chunk of the manufacturing is complete, the products are sent to a facility in Rooma for cosmetic work. The finishing touches include painting, sewing, polishing, and an autoclave that ensures all the layers in a body armor vest are tightly bound together.

As of now, the government of India runs a ballistic testing lab, the Terminal Ballistic Research Laboratory (TBRL) based in Chandigarh, Punjab, but has not yet permitted private entities to dabble in the field of ballistic testing. Rajeev Seth jokes, “[…] Probably because the Hindi dictionary does not have a word for ballistic test, the businesspeople would not know what to call it”. Until further reform, MKU Limited tests ballistic protection products for the international market at their privately-owned ballistic testing lab in Germany.

Having said this, the Rooma Facility has thorough provisions for quality control (QC). Vetted by a number of institutions, Rooma’s quality assurance laboratory enjoys certifications from the British Standards Institution (BSI), Det Norske Veritas (DNV), and Perry Johnson Registrars (PJR).

The Senior Manager of Research and Development at MKU, Rajib Pal, showed BodyArmorNews.com around the famous laboratory that primarily assesses the quality of raw materials. A 13-year veteran at MKU, Rajib explains, “If your raw materials are tested and working, 80 percent of your problem is solved”. To this effect, Rooma’s QC lab drags MKU’s collection of raw materials through hell: there are tests for delamination, fire, elasticity, ceramic quality, moisture wicking, water resistance, water proofness, water repellency, color fastness, bursting strength, tear strength, friction test, an endurance test for Velcro, and a test specifically designed for a helmet’s harness.

Beyond testing the raw materials, a tumbling machine assesses the lifespan of a soft or hard armor insert by modelling the span of five years in ten days. The same is done in a hot air oven and cold ageing cabinet to ascertain the product’s performance in varying climates. There is also an impact absorption test for helmets and a dedicated machine for stab testing.

Back at the Rooma office, where a majority of the company’s R&D takes place, aside from finishing and QC, BodyArmorNews.com was in conversation with Rajib Pal over a cup of Chai. A scholar from IIT Delhi, Rajib is specialized in everything between product engineering, Thermo set resins, and ballistic composite manufacturing. But what makes the Senior Manager’s work special, is his personal touch… As though a compass for his professional trajectory, Rajib’s Father was in the Indian Navy, bringing him a distinct feeling of fulfillment on each successful design. While evaluating a prototype of a hard-armor vest, Rajib wore the gear himself, and sensed an unnecessary weight on his shoulders. A couple of scribbles later, Rajib Pal invented the Insta Load Distribution System (ILDS), an add-on for tactical vests that redistributes the weight of a soldier’s carried load, which may be up to 40 kgs, from the shoulders and spine to the hips and legs, resulting in far greater endurance. Because someone truly cared, this solution is now being supplied to the Indian army.

In the lengthy process of research and development, which often results in failure, Rajib Pal feels supported by MKU Limited’s management team. Recalling his early days at the company, he was entrusted with an expensive project, saying, “That gesture gave me a lot of confidence, knowing that my manager trusts my research despite the very real possibility of failure”.

Upon our persistent questioning on the Kavro Doma 360 helmet, the first boltless helmet to protect the wearer from a round of rifle shots, the Manager of the Helmets Division found time to join our conversation. On the pain-staking process behind the Kavro Doma, Kusumesh Mishra tells,

It took the designing, manufacturing, and testing of 350 prototype helmets before this one was successful.

The brain behind the revolutionary helmet acknowledged that aside from better protecting soldiers, the development of unprecedented technologies tests the limits of scientific knowledge.

Checking Boxes

Consider the realm of sustainability: reusing expired helmets, which take centuries to disintegrate due to their polymer composite base, has been a hot debate in the industry. What is a ballistic protection company to do? The Indian concept of Jugaad (Make-shifting) goes a long way. As a trial project, MKU Limited used old helmets to make bullet-proof shelter houses for the Indian army.

Where there is a will there is a way.

While MKU Limited faces challenges in the sourcing of valuable materials such as II Tubes, Core Processors for Thermal Detection, an increase in Europe’s will to localize instead of buying from the Global South, and the threat of Indian conglomerates such as Tata branching into the defense market, the company’s passion for research, and their core values, a culturally-inbuilt respect for soldiers, are anchors in an industry spanning oceans. BodyArmorNews.com affirms, if no other company has let us into the heart of their business operations, MKU Limited must have nothing to hide.